METAL JACKETED GASKETS

With a high resistance to blow out, metal jacketed gaskets are ideal for high assembly stress situations.

These gaskets are made using a thin metallic outer shell that contains a resilient filler material. The metal casing protects the filler and is resistant to pressure, temperature and corrosion. SMITH Gaskets hand-makes their metal jacketed gaskets and provides them in a variety of shapes and sizes,

with a selection of metals and fillers available.

Best suited to sealing flat surfaces of gas pipes, heat exchangers, cast iron flanges and autoclaves, metal jacketed gaskets can be useful when dealing with irregular or faulty flange rims.

DOUBLE JACKETED GASKETS

|

|

SINGLE JACKETED GASKETS

Single jacketed gaskets have one surface and both OD and ID covered by the metal jacket. Suitable for narrow flange widths in low pressure valve/pump applications. |

Integral Construction

|

|

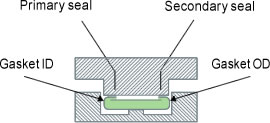

DOUBLE JACKETED GASKETS

Double jacketed gaskets are completed enclosed by a two piece metal covering OD, ID and both sealing surfaces. Widely used in heat exchange applications and suitable for corrosion and high temperature service. |

Welded Construction

|

Ordering information required

Double or single jacket: double |

|

| Camprofiles available upon request. |